Task:

Design a chess set that emphasizes Form, materiality, and Affordance

It was important to create six unique pieces that follow a family of form. Each piece is unique and exclusive to this set but also easily recognizable as the corresponding chess piece.

The set is playable but is also stylized and works well as a striking display piece.

inspiration

The idea of the chess pieces were based on the architecture of St. Basil's Cathedral along with the people of that era. The design and colors of the cathedral give off a very toy-like appearance. Each tower is distinct but also keeps a family of form with the surrounding towers. This relationship of forms is very similar to that of a chess set.

Detailed sketches were drawn as well as silhouettes to try and get more of idea what the forms will look like.

Clay models were made to get a grasp on the scale of the pieces, how they felt in the hands and to test dimensions.

The pieces were modeled using Fusion 360.

Every piece except the pawn was modeled in segments that need to be assembled. this was done for easier and cleaner prints and to avoid needing supports when able.

Quick 3d printed prototypes were made to test materials. A glossy clear coat was added but ultimately decided against because it didn't achieve the desired look.

Using a glossy filament with the lowest layer height was sufficient in giving the pieces a clean presentation.

The Final pieces were printed using an Ender 3 Pro FDM printer. The total print time was around 24 hours since the maximum detail settings were used.

The final pieces were assembled and photographed. Felt circles were attached onto the bottom of each piece to dampen them when set down and to allow them to slide easier on a tabletop or board.

At this stage only one of each piece was printed. After the success of these pieces a full set with a board was planned.

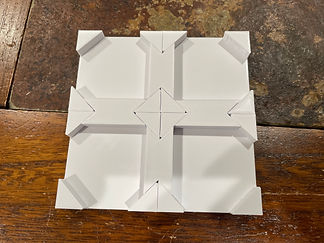

For the board a simple design was modeled in Fusion 360. It was important to design it in a way that ensured all the parts would fit together and that it could be easily mass produced.

The squares where designed to connect using simple connectors. This made it modular and meant only 2 files needed to be sliced and could be printed on repeat.

Prototype prints were made using an Artillery Genius Pro. These took a little bit of trimming but worked even better than expected. With a couple slight modifications to the slicer setting the printer was all set to print all 64 squares plus the connectors.

This printing process took a significant amount of time but was made easy due to the uniformity of the parts.

With all the squares printed the process of assembling began. Plastic superglue was used to bond the parts together and side cutters were used if there was any trimming needed but due to the simplicity of the design trimming was hardly needed.

Using the Artillery printer again the rest of the chess pieces were printed.

With the board finished and chess pieces all printed and assembled the set was complete and ready to be used.